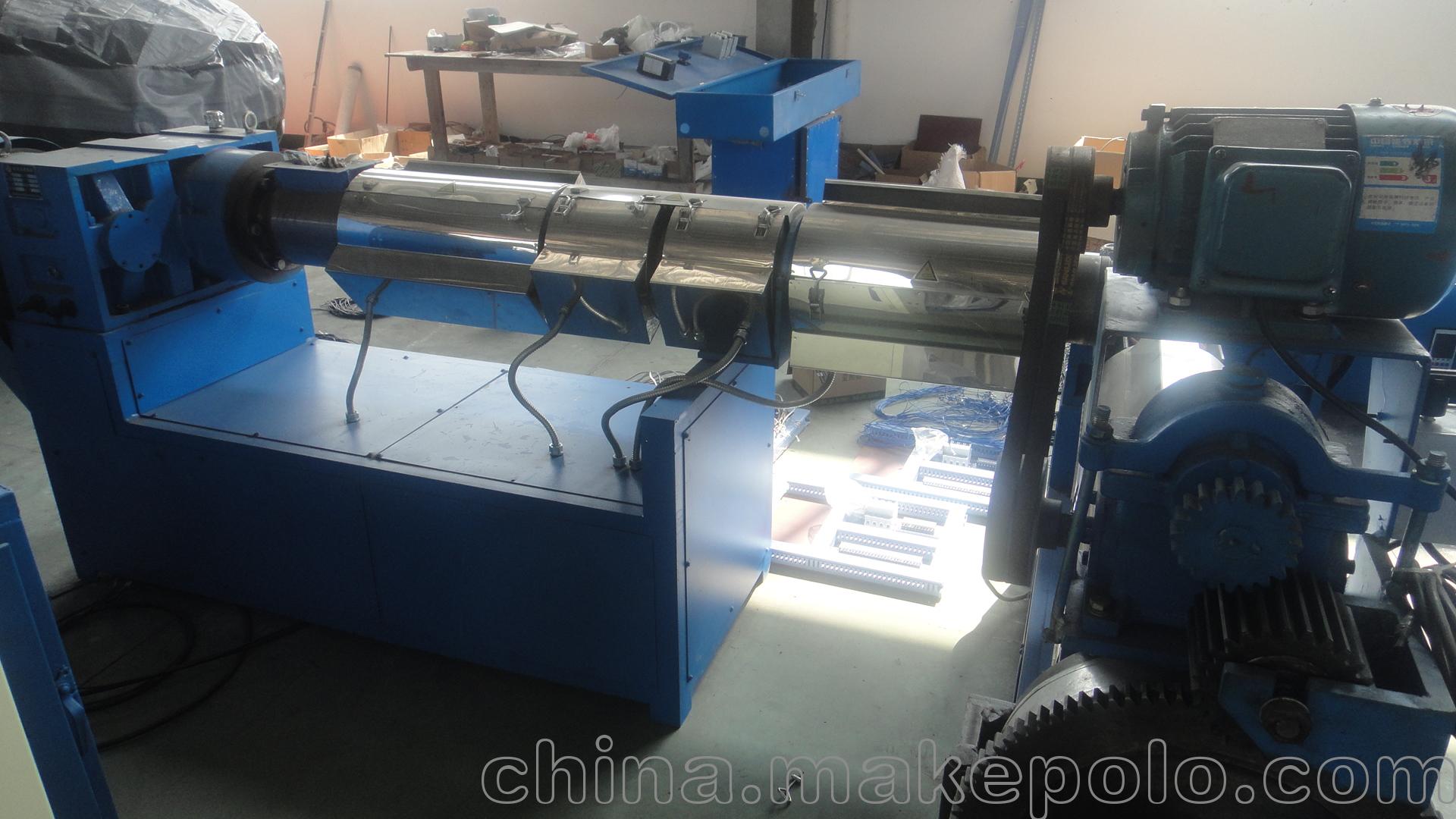

- 品牌:恒瑞克

- 型号:SJ-FMF1800-120

- 类型:塑料复膜机组

- 加工定制:加工定制

- 复合制品宽度:800mm

- 螺杆直径:φ120mmmm

- 螺杆长径比:24:1

- 螺杆转速:10-55m/minr/min

- 挤出机产量:100Kg/hkg/h

- 模口规格:800

- 薄膜厚度单面:2mm

- 薄膜最大折径:2mm

- 电机功率:38KW

- 外形尺寸:880mm

- 重量:500kg

- 11m:22m

- 22m:33m

- 33m:44m

- 44m:55m

- 55m:66m

主 要 配 置 名 称Main scheme name | 型 号 & 参 数 Type & Parameter | 数量 |

系统装机容量 System power | 100Kw |

|

A.挤出主机 Extruding machine |

| 1 |

齿轮箱冷却方式 Gear wheel case |

|

|

螺杆直径 Diameter of screw | φ120mm |

|

长径比 L/D of screw | 24:1 |

|

螺杆转速 Speed of screw | 10-55m/min |

|

螺杆村材质 Material of screw | 38CrMoAlA氮化处理HV740-940 |

|

机筒材质 Material of screw bobbin | 38CrMoAlA氮化处理HV740-940 |

|

压力传感器 Hydraulic inductor |

|

|

螺杆进料式边料组合料斗Screw inputting material style waste mixed hopper |

|

|

电气中央控制盘Electric equipments middle controlled board |

|

|

自动调温仪Automatic adjusting temperature instrument |

|

|

加热区域 Heated scope | 5 |

|

加热功率 Heated power | 47Kw |

|

加热形式 Heating style | 铸铝加热圈Heating loop of casting Al |

|

最大挤出量 Max. Volume of extruding | 100Kg/h |

|

主机电机功率Power of main engine | 37Kw |

|

B.复合装置 Compound device |

| 1 |

硅胶辊直径 Rubber roller | φ200mm |

|

冷却钢辊 Steel roller | φ400mm |

|

牵引电机功率 Tow engine power | 11Kw |

|

冷却方式 Cooling style | 水冷Water cooling |

|

接口 Connecting place | 3/4” |

|

模头宽度 Width of mold | 1800mm |

|

加热区域 Heating scope | 五区 |

|

加热形式 Heating style | 铸铝加热板Heating board of casting Al |

|

主 要 配 置 名 称Main scheme name | 型 号 & 参 数Type & Parameter | 数量 |

模头夺厚度调节范围Adjusting scope of mold width | 0.1-0.55mm |

|

B.切边。打孔,废边吹送装置Cutting side device |

| 1 |

切边方式 Cutting side style | 刀片式Knife piece style |

|

风机功率Wind machine power | 1.5Kw |

|

针盘,针槽Needle check , needle trough |

|

|

打孔针规格 specification of needle | φ1.4-φ2.5mm |

|

C.裁切装置Cutting device |

| 1 |

裁切方式Cutting style | 冷切Cold cutting |

|

最大裁切长度Max. cutting length | 1200mm |

|

D.收卷装置 Winding device |

| 1 |

收卷方式 Winding style | 表面卷取Surface winding |

|

收卷速度Winding style | 20-80m/min |

|

收卷辊直径Diameter of winding bobbin | φ190mm |

|

收卷电机功率Winding power | 7.5Kw |

|

最大卷径. winding diameter | 1000mm |

|

E.放卷装置Putting device |

| 1 |

工位数Working place number | 双工位Double working place |

|

纠偏方式correcting an error style | 液压纠偏Hydraulic pressure correcting an error |

|

F.设备外形尺寸Overall dimension t | 10000×8000×3000mm |

|

G.整机重量Weight | 8000Kg |

主 要 配 置 名 称Main scheme name | 型 号 & 参 数 Type & Parameter | 数量 |

系统装机容量 System power | 100Kw |

|

A.挤出主机 Extruding machine |

| 1 |

齿轮箱冷却方式 Gear wheel case |

|

|

螺杆直径 Diameter of screw | φ120mm |

|

长径比 L/D of screw | 24:1 |

|

螺杆转速 Speed of screw | 10-55m/min |

|

螺杆村材质 Material of screw | 38CrMoAlA氮化处理HV740-940 |

|

机筒材质 Material of screw bobbin | 38CrMoAlA氮化处理HV740-940 |

|

压力传感器 Hydraulic inductor |

|

|

螺杆进料式边料组合料斗Screw inputting material style waste mixed hopper |

|

|

电气中央控制盘Electric equipments middle controlled board |

|

|

自动调温仪Automatic adjusting temperature instrument |

|

|

加热区域 Heated scope | 5 |

|

加热功率 Heated power | 47Kw |

|

加热形式 Heating style | 铸铝加热圈Heating loop of casting Al |

|

最大挤出量 Max. Volume of extruding | 100Kg/h |

|

主机电机功率Power of main engine | 37Kw |

|

B.复合装置 Compound device |

| 1 |

硅胶辊直径 Rubber roller | φ200mm |

|

冷却钢辊 Steel roller | φ400mm |

|

牵引电机功率 Tow engine power | 11Kw |

|

冷却方式 Cooling style | 水冷Water cooling |

|

接口 Connecting place | 3/4” |

|

模头宽度 Width of mold | 1800mm |

|

加热区域 Heating scope | 五区 |

|

加热形式 Heating style | 铸铝加热板Heating board of casting Al |

|

主 要 配 置 名 称Main scheme name | 型 号 & 参 数Type & Parameter | 数量 |

模头夺厚度调节范围Adjusting scope of mold width | 0.1-0.55mm |

|

B.切边。打孔,废边吹送装置Cutting side device |

| 1 |

切边方式 Cutting side style | 刀片式Knife piece style |

|

风机功率Wind machine power | 1.5Kw |

|

针盘,针槽Needle check , needle trough |

|

|

打孔针规格 specification of needle | φ1.4-φ2.5mm |

|

C.裁切装置Cutting device |

| 1 |

裁切方式Cutting style | 冷切Cold cutting |

|

最大裁切长度Max. cutting length | 1200mm |

|

D.收卷装置 Winding device |

| 1 |

收卷方式 Winding style | 表面卷取Surface winding |

|

收卷速度Winding style | 20-80m/min |

|

收卷辊直径Diameter of winding bobbin | φ190mm |

|

收卷电机功率Winding power | 7.5Kw |

|

最大卷径. winding diameter | 1000mm |

|

E.放卷装置Putting device |

| 1 |

工位数Working place number | 双工位Double working place |

|

纠偏方式correcting an error style | 液压纠偏Hydraulic pressure correcting an error |

|

F.设备外形尺寸Overall dimension t | 10000×8000×3000mm |

|

G.整机重量Weight | 8000Kg |