- 品牌:vj

- 型号:XQuik II 点料机

- 触发方式:同步计数器

- 计数器进制:任意进制计数器

- 计数方式:其他

- 计数范围:1

- 输入信号:2

- 信号方式:11

- 输入信号电压:50V

- 开孔尺寸:12mm

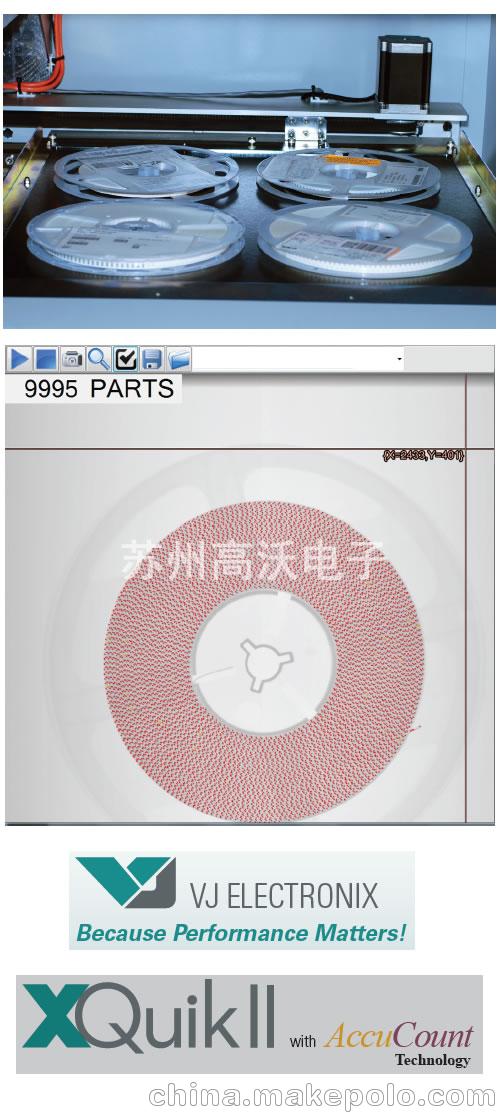

XQuik II is a compact benchtop X-ray inspection system for inspecting small items with varying density. Now, with AccuCount technology, the XQuik II is even more versatile allowing for component reel counting in just seconds.

• Compact size: Small in size, but not capability. XQuik II occupies much less space than typical X-ray inspection systems.

• Simple, intuitive image sharing: storing and sharing images via cloud or any storage of your choice to provide access to multiple people at once.

• Quick image processing: Intuitive Vi3 imaging software captures images in no time and releases them to the user to identify defects.

• Easy set-up and use: Installation is quick and easy, eliminates long hours for training operators.

VJ Electronix,Inc.,返工技术及先进的 x 射线检测和计数系统,组件的全球供应商的领导者介绍了组件卷轴交其受欢迎的 XQuik II 与 AccuCount 系统的自动化。

VJ Electronix 添加到 XQuik II 组件处理自动化

革命性的 XQuik II AccuCount 技术是现在比以往更快。与可用物料搬运自动化,XQuik 系统自动计数组件在最原始速度的两倍多。

新的两级式输送机提供自动加载和卸载的卷轴。操作员可以扫描条形码、 应用标签和扫描时传送卷轴和计数的下一个卷轴发生 — — 提供显著的吞吐量增加。

根据对产品经理,弗兰克森”XQuik 将返回组件到股票的时间减少。 更快的存货周转率降低成本,消除了线下事件由于存货短缺的风险。

XQuik 一次处理一个绗缝卷轴或四 7 ″ 卷轴。自动计数算法意味着不需要编程操作。易于定制的 MES 接口消除了手动数据输入、 保存更多的时间和消除人为错误的风险。

Key Features

• Automatically “counts” components as small as 01005

• Counts 7" to 15" reels

• One button operation

• Reduce cycle times

• Integrated barcode printing

• Connect to MES for seamless inventory control

• Substantially speed up part counting process

• >99% part count accuracy

• May also be used for electronics inspection

Cabinet Dimensions

External Dimensions: 42.5" x 30" x 40"

Chamber Size: 16.25" x 16.25" x 6"

Viewable Area: 16" x 16"

• Imaging Station

Image resolution: 54μ pixel pitch

Line pair resolution: 7 Ip/mm

• Imaging Software Features

Image archiving

Window leveling

Digital zoom

Annotations

• X-ray Specifications

Beam orientation: Top, Down

Normal Anode Voltage: 40–80 kV

Normal maximum anode current: 0.7mA

苏州高沃电子为了进一步服务好汽车电子、高铁、航电、军工、5G等行业,主要提供以下解决方案:1.美国DATA I/O的汽车电子芯片全自动烧录器,DATA I/O是世界领先的编程烧录设备生产商,成立于1972年,生产了全球第一台编程器,并与1982年在美国纳斯达克上市。主要有PSV7000,PSV5000,PSV3000,PSV2800,ROADRUNNER,FLASHPAK III,PS588,LumenX,FlashCore,ConneX。2.日本I-BIT (原松下X光事业部)3D-Xray检测设备,用3D-X射线CT断层扫描高速检测出2D-X光机无法检测出的焊接缺陷:双面贴装基板、BGA虚焊空焊、接插件通孔透锡不良、IGBT焊接空洞、堆叠封装芯片等等。高速X射线CT分层检测对产品可靠性有显著提高,在产品出厂之前发现隐蔽缺陷,致召回成本和不良率降到最低。主要产品有:在线3D-X射线断层扫描自动检测系统:ILX-1100,ILX-2000离线3D-X射线高速断层扫描检测系统:FX-300tRX,FX-400tRX3.美国VJ SRT返修台,X-Ray点料机。主要产品:Summit 1800i,Summit 750i,VJE XQuik AccuCount,VJE XQuik II with AccuCount。苏州高沃电子有限公司SUZHOU GOVO TEK LIMITED地址:苏州市吴中经济开发区天鹅荡路2号友新工业园B3栋3楼邮编:215000电话:0512-66035036传真:0512-66035035手机:吴先生 15851445511邮件:phil@govotek.com